A)Types of marine cages for fish farming

Steel cages:

This type of cage is more desirable due to the greater safety of the staff and the presence of corridors, fences, non-polished surfaces, mechanization and easy operating operations. Its frame can be made of galvanized, steel or aluminum cladding so that it is mechanically strong as well as resistant to corrosion and its components can be easily repaired and replaced. It has good strength against waves and sea currents. The timber frame is mounted on floating pads or foam. Its grid is similar to polyethylene cages and is designed to be floating, square, or rectangular. It is generally installed in areas close to the beach and bunker (behind an island or on the coastline).

Floating polyethylene cages:

The frames of these cages are made of flexible polyethylene pipes, which are fastened by steel hooks or vertical pipes and have a fence with a brace. Mounting the parts is done by welding polyethylene pipes and by heat welding machines. The entire cage farm is interconnected as a rope network at a depth of 4-4 meters (depending on the maximum wavelength). The floating polyethylene ring is the main factor in maintaining fish breeding nets.

This type of cage is cheaper than other cages and has a simple structure so that at the water surface two to three rows of high pressure polyethylene pipe circular and below the surface as the following form of rope, chains, plates. Split, shape, anchor and nylon nets are formed. It can be installed in the open sea at depths of 40 – 20 meters. Its weaknesses can be reduced to a mesh volume (shrinkage) at a flow rate of five tenths of a second (one node) and continued to 60% by volume at a flow rate of one meter / second (two nodes).

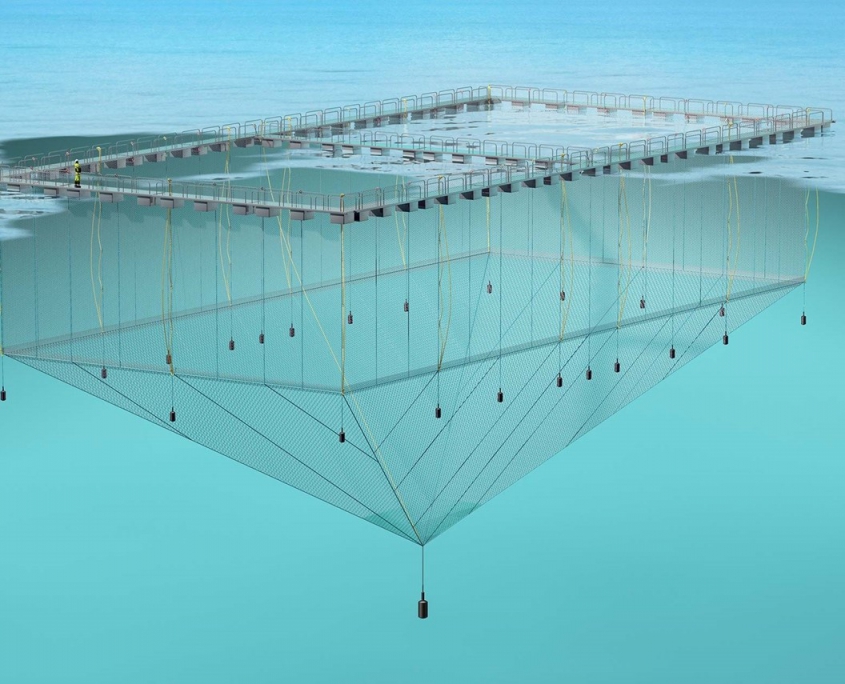

Immersed polyethylene cages:

This type of cage is designed with the energy of the waves of the sea. As the depth increases, the energy of the waves decreases continuously, so that seawater is at half the wavelength for a calm, stress-free fish. The cage anchors are positioned vertically just below the cage. In stormy conditions the cage acts in the direction of sea currents, but with the continuous motion of the waves it is almost similar to the seaweed, thus reducing the pressure on all parts of the cage by resisting the waves.

In stormy weather, when the surface of the sea faces a significant wave motion, the cages move in the direction of the waves and go deeper so that the fish are sheltered in the deeper, deeper layers of the sea. The cages are arranged in duplicate rows with a large space at the center of the marine farm, respectively. With this type of deployment, easy access to all cages is ensured and abundant sea water exchange is ensured. Depth of installation due to the use of vertical restraint system has no effect on cage position and it is recommended that fish farms should be located in open sea areas that are at least 30 meters deep. The level of occupancy in tensile base cages and their equipment is significantly lower than in other cages.

Semi-submerged and submerged spherical cages:

This cage is a product of 2009 and is designed and built in three models, available in 212, 3700 and 7820 cubic meters. It is made of polyethylene and FRP and has a depth of 60 meters.

This type of cage is one of the most robust offshore structures, as it withstands eighteen yards of waves and exhibits exceptional rotation and flexibility with its special restraint network. The high price of the cage can be its disadvantages.

Semi-submerged plate-shaped cage:

Offshore areas with high seawater resistance capability (maritime Dodgers) are used as offshore stations. It has a three-point harness grid and is designed to withstand the sea currents without reducing the volume of the mooring and being half submerged. Its shape is roughly similar to two cones that are attached to the base. Changing the nets and harvesting the fish is done mechanically and is very suitable for stormy conditions.

B)Cages appropriate to the conditions of different regions of the country

Suitable cages for Oman and Caspian Sea:

Due to the environmental conditions and the high waves in these areas (temperature and wave height), the type of cage is different. Immersed floating polyethylene round cage, TLC base and submerged spherical are the most suitable type to cope with sea currents and high waves. The size of this cage varies from 1800 to 3600 cubic meters. The immersed polyethylene cage is primarily designed for breeding salmon and salmon due to the rising water temperature in the Caspian surface layers in summer and the necessity (16 to 20 m depth and 16 to 18 ° C). Different environments prefer different environments and as a result different structures have to be used to grow them.

For example, polyethylene floating cages should be used for breeding species such as elephants due to their specific conditions. Due to the lower mouth, nutritional conditions often favor the nutrition of the foam, so having a tray is essential.

Consideration is given to the construction of cages tailored to the biological needs of each species that prefer a particular habitat, and this should be taken into account when designing cages for new species.

Suitable cages for Persian Gulf waters:

These polyethylene cages, measuring 1,300 to 1,600 cubic meters, are cylindrical and fully restrained on both sides, with two to three rows of tubes for increased buoyancy, and can be mounted near and offshore.