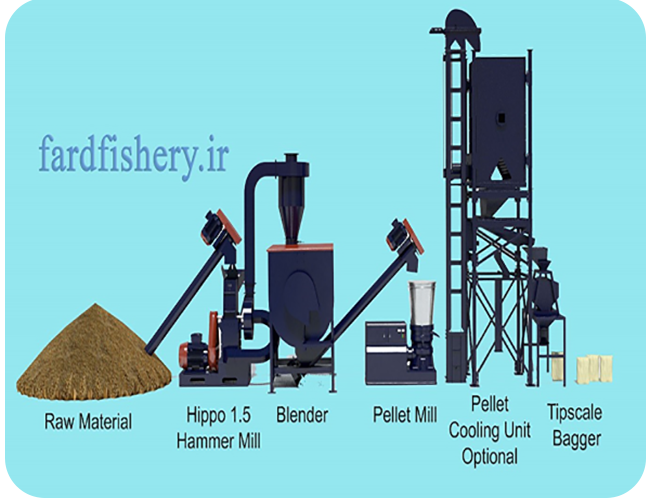

Food processing machinery and supplies

Before we provide a detailed explanation of feed production methods, we invite you to join us in introducing food making machinery and supplies.

1) Balances:

Balances are an essential part of all aquaculture feed factories to accurately weigh the raw materials needed for feed production.

2) Mills:

Grinding means reducing the particle size of the raw materials, the types of mills include abrasive or plate mill and hammer mill.

3) Meat Grinder:

It is needed in making wet or moist foods and is able to blend raw food ingredients together and create a harmonious composition.

4) Mixers:

There are two types of dry or wet mixers or mixers that are horizontal or vertical.

5) Elevators and Transmitters:

They are tools for conveying feedstock to other areas, sometimes horizontally and sometimes vertically.

6) Pelletizers:

The pelletizing process in the pellet press means pressurizing soft mixed materials through metal plate holes to form compressed filaments and then cut, at the top of these devices, a container for adding liquids such as water or molasses. They are embedded in different sizes and dimensions.

7) Extrusion baking machine:

These machines are mostly designed for large centers and are capable of producing food with proper buoyancy.

8) Coolers, dryers:

Extruded pellets have a temperature of 88 ° C and a humidity of 17 to 18%, pellet temperatures should reach ambient temperatures quickly and reach a humidity of 10 to 12 using cooling. Done.

Other tools are used in the manufacturing process that can be summarized as: grease dispensers, boilers, freezers, crushers, gaskets and embroideries.